Imagine a world of CNC machining where tool setup is a time-consuming guessing game. Enter the tool presetter, a precision instrument that streamlines the process, saving manufacturers time and money. The tool presetter market, catering to this valuable technology, is experiencing significant growth driven by several key trends. Let’s explore the functionalities of tool presetters and delve into the factors propelling this market forward.

Taking the Guesswork Out of Tooling: Applications of Tool Presetters

Tool presetters offer a range of benefits for CNC machining operations:

- Precise Tool Measurement: Presetters eliminate the need to manually measure tools on the CNC machine itself. They utilize high-accuracy sensors to measure tool length, diameter, and other critical dimensions.

- Reduced Setup Times: By pre-measuring tools offline on the presetter, operators can significantly reduce setup times on the CNC machine, leading to increased productivity.

- Improved Machining Accuracy: Pre-setting tools ensures consistent and accurate tool positioning, leading to higher-quality machined parts and reduced scrap rates.

- Tool Breakage Prevention: Presetters can detect wear and tear on cutting tools, allowing for preventive maintenance and preventing costly tool breakage during machining.

- Reduced Machine Downtime: Minimizing setup times and preventing tool failures on the machine translates to less downtime and improved overall machine utilization.

Get Exclusive Sample Copy of the Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-17620

A Market on the Rise: Growth Factors Shaping the Future

The tool presetter market is experiencing steady growth fueled by several key factors:

- Rise of Automation in Manufacturing: The increasing adoption of automation in machining necessitates faster and more reliable tool setup processes, driving the demand for tool presetters.

- Focus on Precision Machining: As product complexity and tolerances continue to decrease, the need for precise tool pre-setting to ensure consistent part quality becomes paramount.

- Growing Demand for High-Volume Manufacturing: In high-volume production environments, minimizing setup times and maximizing machine uptime are crucial. Tool presetters offer a significant efficiency advantage.

- Advancements in Tool Presetter Technology: Developments in sensor technology, automated tool loading systems, and integration with CNC machines are leading to faster, more user-friendly, and more versatile tool presetter models.

- Increased Awareness of Benefits: As awareness of the cost-saving and productivity-enhancing benefits of tool presetters spreads, the market is expected to see continued growth.

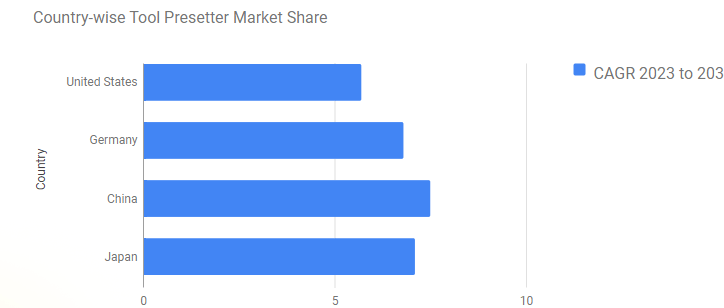

The Tool Presetter market is poised for significant growth, with a projected worth of USD 1,265.9 million by 2023. By 2033, it is anticipated to surpass USD 2,109.5 million, exhibiting a robust compound annual growth rate (CAGR) of 6.4% throughout the forecast period. This expansion is primarily driven by the burgeoning electronics industry worldwide and the proliferation of manufacturing plants, both of which are pivotal factors fueling the global tool presetter market’s expansion.

Challenges and Considerations

The tool presetter market also faces some challenges:

- Initial Investment Costs: High-performance tool presetters can involve a significant upfront investment, which may deter smaller machine shops.

- Shop Floor Integration: Integrating tool presetters seamlessly with existing workflows and CNC machines might require adjustments to shop floor layouts and training for operators.

- Skilled Personnel: While tool presetters are user-friendly, understanding proper tool measurement techniques and interpreting presetter data remains essential for optimal results.

Get Full Report Now: https://www.futuremarketinsights.com/checkout/17620