Imagine a future where robots seamlessly collaborate with humans on the factory floor, not as replacements, but as helpful companions. This vision is becoming reality thanks to the Collaborative Robots Market (Cobot Market), a sector dedicated to a new generation of robots – the cobots. Unlike their bulky, industrial cousins, cobots are designed for safe interaction with people. They are smaller, lighter, and equipped with features like intuitive programming and built-in safety measures. This human-centric approach is revolutionizing various industries by enabling collaborative work between humans and robots, leading to increased productivity, improved worker safety, and exciting new possibilities. Driven by rising labor costs, a growing demand for flexibility in manufacturing, and a focus on human-robot collaboration, the Collaborative Robots Market is experiencing significant growth. Let’s delve into the diverse applications of cobots and explore the exciting trends shaping this dynamic market.

Working Together, Working Smarter: Applications of Collaborative Robots

Cobots are making their mark across a wide range of applications in various industries:

- Assembly Lines: Cobots can perform repetitive tasks like picking and placing parts, freeing up human workers for more complex assembly processes, improving overall line efficiency.

- Material Handling: Cobots can assist with tasks like loading and unloading machines, palletizing finished goods, and handling heavy or bulky materials, reducing the risk of workplace injuries.

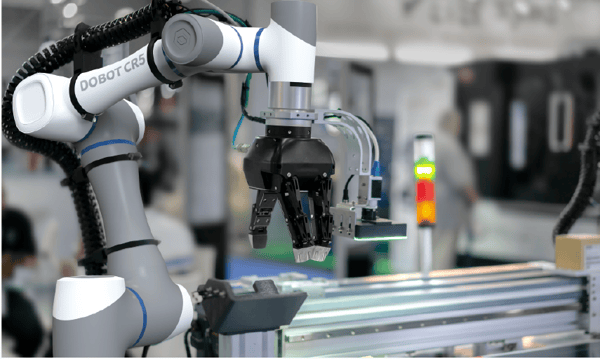

- Machine Tending: Cobots can efficiently load and unload materials into CNC machines, lathes, or other automated equipment, optimizing machine uptime and production output.

- Quality Control: Cobots equipped with vision systems can perform visual inspections, identify defects, and ensure product quality, enhancing consistency and reducing human error.

- Surface Finishing: Cobots can handle tasks like sanding, polishing, and deburring, allowing human workers to focus on higher-level finishing processes that require a more delicate touch.

Get Exclusive Sample Copy of the Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-8641

A Spectrum of Cobot Solutions: Catering to Diverse Needs

The Collaborative Robots Market offers a variety of cobot designs and functionalities to cater to different applications and production environments:

- Single-Arm Cobots: These versatile robots have a single arm for performing various tasks, offering a space-saving solution for smaller workspaces.

- Dual-Arm Cobots: These cobots mimic human arms with two arms, allowing for more complex tasks like grasping objects and manipulating them in multiple directions.

- Mobile Cobots: Mounted on mobile bases, these cobots can move around the workspace, offering greater flexibility for tasks requiring wider reach or frequent relocation.

- Vision-Enabled Cobots: Equipped with vision systems, these cobots can perform tasks that require visual recognition and precise positioning, expanding their application range.

- Easy-to-Program Cobots: Many cobots are designed for intuitive programming, allowing even workers without extensive robotics knowledge to set them up and operate them efficiently.

The global collaborative robots market is projected to record a high-paced CAGR of 25.1% during the forecast period. The current valuation of the collaborative robots market is USD 2.2 billion in 2023 and is anticipated to reach a high of USD 20.5 billion, by the year 2033.

A Market Full of Potential: Growth Drivers in Collaborative Robots

The Collaborative Robots Market is experiencing a surge in popularity driven by several key trends:

- Rising Labor Costs: As labor costs increase, manufacturers are seeking automation solutions to improve productivity and reduce reliance on human labor. Cobots offer a cost-effective way to automate specific tasks without large-scale infrastructure changes.

- Focus on Flexibility: Manufacturing environments are becoming more dynamic, with shorter production runs and frequent product changes. Cobots with their easy deployment and reprogramming capabilities cater well to this need for flexibility.

- Safety for Humans: Cobots are designed with safety in mind, featuring sensors and limitations that prevent them from harming humans working in close proximity. This focus on safety allows for true collaboration between humans and robots.

- Technological Advancements: Advancements in areas like artificial intelligence, vision systems, and intuitive programming are making cobots more capable, versatile, and user-friendly, expanding their application potential.

- Small and Medium-Sized Enterprises (SMEs): The affordability and ease of use of cobots make them accessible to SMEs that may not have the resources for traditional industrial robots. This opens doors for greater automation opportunities across various industries.

Get Full Report Now: https://www.futuremarketinsights.com/checkout/8641