In environments where flammable gases, vapors, or dust particles exist, even a tiny spark can ignite a catastrophic explosion. Here’s where explosion-proof motors step in, acting as the muscle behind safe operations in hazardous zones. These specially designed motors are engineered to withstand or prevent explosions, ensuring the continued operation of equipment and the safety of personnel. Driven by stringent safety regulations, the growing demand for energy exploration and production, and a rising focus on worker well-being, the Explosion-Proof Motor Market is experiencing steady growth. Let’s take a closer look at the applications of explosion-proof motors and delve into the exciting trends shaping this dynamic market.

Defusing Danger: Applications of Explosion-Proof Motors

Explosion-proof motors come in a variety of configurations and sizes, each designed to address specific hazardous environments:

- Oil & Gas Industry: From offshore drilling platforms to refineries, explosion-proof motors are essential for safe operation. They power vital equipment like pumps, compressors, and ventilation systems, ensuring reliable performance without igniting flammable hydrocarbons.

- Chemical Manufacturing: Chemical plants handle volatile materials that can easily ignite. Explosion-proof motors power mixers, agitators, and other processing equipment, minimizing the risk of explosions and safeguarding workers.

- Pharmaceutical Production: Pharmaceutical manufacturing facilities often utilize flammable solvents and powders. Explosion-proof motors power equipment like dryers, blenders, and dust collection systems, preventing explosions that could endanger personnel and disrupt production.

- Grain Handling Facilities: Grain dust is highly combustible. Explosion-proof motors power grain elevators, conveyors, and other equipment, mitigating the risk of explosions during grain storage and processing.

- Painting and Finishing Operations: Paint booths and areas where flammable solvents are used require explosion-proof motors to power ventilation systems, pumps, and other equipment, minimizing ignition risks and ensuring worker safety.

Get Exclusive Sample Copy of the Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-19162

A Market Sparking with Opportunity: Growth Factors and Trends

The Explosion-Proof Motor Market is experiencing a surge in popularity driven by several key trends:

- Stringent Safety Regulations: Governments worldwide are implementing stricter regulations regarding workplace safety in hazardous environments. This mandates the use of explosion-proof equipment, including motors, in high-risk industries.

- Focus on Worker Safety: Companies are prioritizing the safety of their employees. Investing in explosion-proof motors demonstrates a commitment to worker well-being and helps prevent costly accidents.

- Growth in Energy Exploration and Production: The increasing demand for oil and gas is driving exploration and production activities in new and potentially volatile environments. This necessitates the use of explosion-proof motors to ensure safety during these operations.

- Advancements in Technology: Manufacturers are constantly innovating, developing explosion-proof motors with improved functionality, enhanced durability, and better integration with advanced monitoring and control systems.

- Focus on Sustainability: Explosion-proof motor manufacturers are developing solutions that minimize energy consumption and reduce emissions, contributing to a more sustainable future for hazardous environment operations.

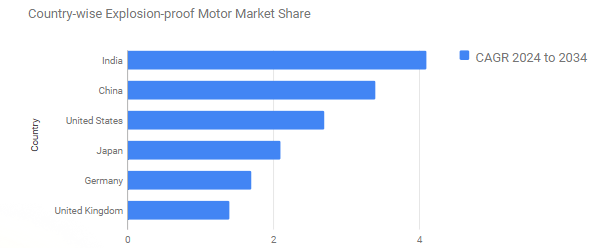

The global explosion-proof motor market size is forecast to increase from USD 3,602.2 million in 2024 to USD 5,540.8 million by 2034. Over the assessment period, global demand for explosion-proof motors is projected to surge at a CAGR of 4.4%.

Challenges and Considerations

The Explosion-Proof Motor Market also faces some hurdles:

- High Initial Investment: Explosion-proof motors can be expensive compared to standard motors. However, the long-term benefits in terms of safety, reduced downtime due to accidents, and worker well-being can outweigh the initial cost.

- Regular Maintenance and Inspection: Explosion-proof motors require regular maintenance and inspections to ensure optimal performance and continued safety. Implementing robust maintenance protocols is crucial.

- User Training: Proper training for personnel on the safe operation and use of explosion-proof motors is essential to prevent misuse and maintain a safe working environment.

Get Full Report Now: https://www.futuremarketinsights.com/checkout/19162

Field Erected Cooling Tower Market Analysis: Industry worth USD 3.5 billion by 2034

Flexographic Printing Market Value Soaring at USD 14.7 billion by 2034

Warehouse RFID Market Projected to Reach USD 23,561.8 million by 2034