Future Market Insights (FMI), in its latest research, evaluates the vibrating screen market which includes global industry analysis 2014–2018 and opportunity assessment 2019–2029. The report investigates the vibrating screen market and provides critical insights for the forecast period of 2019-2029. As per the research, the global vibrating screen market was valued at ~ US$ 1 Bn in 2018, and is estimated to increase at a CAGR of ~7% between the forecast period of 2019 and 2029.

Upswing in mining processes to suffice the requirement for precious metals and hard rock minerals as well as in construction activities to build infrastructure assets is the messiah of pain points of the global vibrating screen market, suggests FMI. On the contrary, the growth trail will get hindered by tumbling mining operations on grounds of environmental amendments to curb carbon footprint and high attrition rate among miners due to on-site adversaries.

- To Get a Sample Copy of the Report visit @ https://www.futuremarketinsights.com/reports/sample/rep-gb-1789

2014-2021 Vibrating Screen Market Outlook in Comparison to 2022-2029 Growth ForecastFocus on innovations is at its peak in the vibrating screen market. Manufacturers are integrating state-of-the-art technologies to ascertain greater efficiency.

For instance, focus on developing ultrafine vibrating screens featuring a collective assembly of up to ten separate screen decks, as well as a feed splitter box is expected to bolster the sales in this vibrating screen market.

These new innovations are expected to aid in the accurate distribution of feed across the deck. At the same time, these are likely to lower the initial capital investment, enhance the overall efficiency, and eliminate the need for bigger pumps, such as hydro-cyclones.

Besides this, the integration of hydro-cyclone feed pumps with vibrating screens in a 2-phase classification circuit enables better operational Return on Investment (ROI). Thus, various manufacturers are striving to develop state-of-the-art products to consolidate higher percentage of share within the market.

They also have \started adopting polyurethane and steel-reinforced rubber for the manufacturing of these screens to prevent vibrations from occurring at the side plates. Additionally, they are including self-tensioned motor-bases to shield both the drive belts and electric motor from the high tension cause due to vibrations.

To ensure workforce safety, many key players are replacing the conventional nuts and bolts with huck-bolted screens. They are even eliminating the requirement of lifting tools by pairing the sliders with the front chutes. It is thus not only providing an easy access but also allowing smooth movements of the screen.

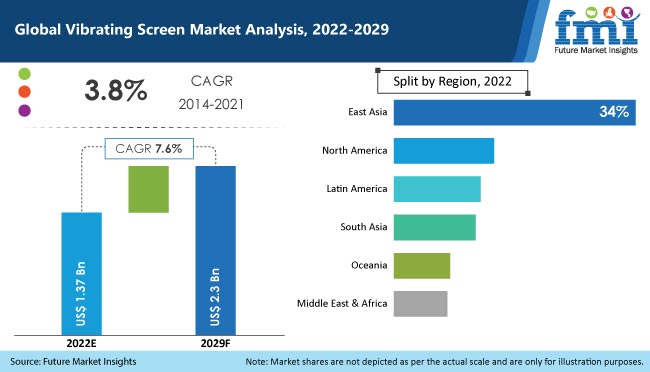

Spurred by aforementioned developments, the vibrating screen market is expected to register 7.6% CAGR between 2022 and 2029, up from 3.8% CAGR recorded during 2014-2021.

Vibrating screens have been hitting the mark with innovations over the years as sieving equipment in grading and screening of the required material, which would have been otherwise impossible. FMI’s study suggests that major market players are including add-ons to the existing and new equipment for better screening efficacy and elongated life-cycle.

Request Complete TOC Of this Report @ https://www.futuremarketinsights.com/toc/rep-gb-1789

Demand for Circular Vibrating Screens in Mining Industry to See an UpturnCircular vibrating screens are inundating more than half of the market revenues, as per FMI’s study. The mining industry, including coal mines, and quarrying sites, is leveraging circular vibrating screens owing to their ability to classify materials with large specific gravity, large particles and great rigidity. The exciter of circular vibrating screens is mounted above the center of gravity of the screen box and the upper tip of elliptical long axis of the feeding end is positioned towards the leakage direction, which results in higher processing capacity per unit time than that of its linear counterpart.

On the flip side, the complexity of shakers and fast-rate rotation of the two shafts in linear vibrating screens imply high fueling demands. Further, the FMI’s study finds that linear vibrating screens are chiefly utilized for classification of fine particles, light weight, and low stiffness materials, making them suitable for industries such as, building materials, chemical, and pharmaceutical.

Manufacturers showing Stauncher Inclination toward Direct Drive SystemAs per the FMI’ report, adoption of direct drive system in vibrating screen accounts for more than 50% of the market revenues owing to the absence of gearboxes and belts in the design, which results in lesser wear and tear between the components. The direct drive system is cost-efficient as the moving parts in the operation and framework are less complicated. For noise abatement, the direct drive system comes up with simple arrangement and lesser moving components which may vibrate during mechanism. Furthermore, the reduced number of kinetic parts prevent easy loss of energy due to friction, enabling better efficacy, improved accuracy and increased life-cycle of the vibrating screen components. The indirect drive system, on the other hand, is subjected to friction between constituents including, gears, couplers, and pulleys, implying decreased efficiency and precision.

Vibrating Screen Market by CategoryProduct Type:

- Linear Vibrating Screens

- Circular Vibrating Screens

- Elliptical Vibrating Screens

Drive Type:

- Direct Drive

- Indirect Drive

End-use Industry:

- Construction

- Mining

- Recycling

- Others (Iron & Steel, Power, etc.)

Region:

- North America

- Latin America

- Europe

- East Asia

- South Asia

- Oceania

- Middle East & Africa