The global gummed tapes market is estimated to expand at 6% CAGR between 2021 and 2031, find Future Market Insights (FMI). These tapes are most preferred for sealing heavy equipment, furniture, and other bulky items to reduce the risk of damage during the transportation of the products.

Sales of these tapes are expected to burgeon on the back of surging application in various end-use industries such as food & beverages, electricals & electronics, printing, and others. The excellent bond forming ability, resulting into better sticking and gluing properties of gummed tapes will also fuel the demand.

Request Sample Report @ https://www.futuremarketinsights.com/reports/sample/rep-gb-2821

These tapes perform well in the normal temperature ranges once applied to the corrugated box. They also provide ease and convenience to seal the box with the highest level of safety and security to the box and also can be easily opened without the use of cutting tools.

On the back of such aforementioned factors, the global gummed tapes market is projected to surpass US$ 1.9 Bn by the end of 2031.

Competitive Landscape

3M Company, Intertape Polymer Group Inc., Shurtape Technologies LLC, Holland Manufacturing Co., Inc., Loytape Industries Sdn Bhd, Papertec Inc., LPS Industries LLC, Windmill Tapes & Labels Ltd., Neubronner GmbH & Co., KG, Maxfel Srl, Can-Do National Tape, Suzhou Tongxie Adhesive Tape Co., Ibergum S.A., and Waterproof Corporation Pvt. Ltd. are key players operating in the global gummed tapes market.

Key Takeaways:

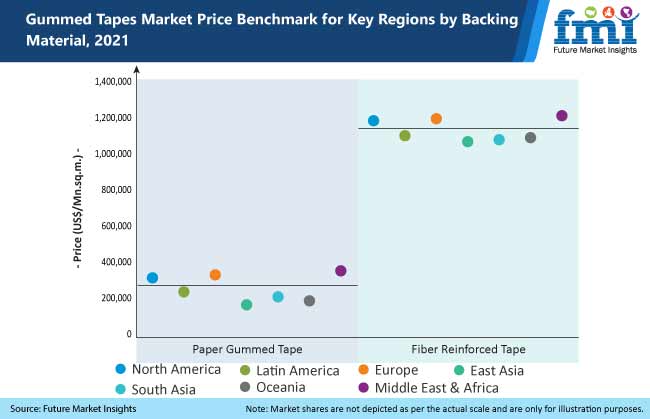

- By backing material, the fibre reinforced tape is expected to hold around 90% of the market by 2031.

- Brown gummed tapes segment is forecast to hold maximum share in the global market registering 6% CAGR during the assessment period.

- In terms of adhesives, the starch adhesives is projected to expand by 2x over the next decade.

- Based on application, the splicing segment is poised to expand at a CAGR of 7.5% by 2031, registering year-on-year growth by 8% during 2025-2027.

- By end use, shipping & logistics, food & beverages segment and electrical & electronics segment are anticipated to, collectively, hold around 40% of the market share.

- North America, Europe, and East Asia are projected to hold approximately 65% of the market share by the end of 2031.

“Increasing need for enhanced product safety and improved package sealing solutions across shipping & logistics, electrical & electronics, and building & construction industries is propelling the demand for gummed tapes. Expansion of aforementioned end-use industries in East Asia is expected to create growth opportunities for market players.” says an FMI analyst.

Elimination Of The Gluing Step To Fuel The Sales Of Gummed Tapes

The tapes applied with glue have the risk of falling off from the product or container as the temperature or weather conditions changes. Therefore, this not only leads to the defect in the sticking but also affects the product safety by increasing the risk of product damage during the transportation process.

Use of gummed tapes eliminates the gluing step and thereby makes the sticking and tape application process easy. This also saves time along with the better sticking and adhesion properties as compared to the traditional tapes.

MENA Industrial Packaging Market By Category

By Product:

- Plastic Pallets

- Drums

- IBCs (Totes)

- Sacks

- Pails

- Crates

- Tubes

- Bulk Boxes

- Other

By Material:

- Metal Industrial Packaging

- Plastic Industrial Packaging

- Paper & Paperboard Industrial Packaging

- Fiber & Wood Industrial Packaging

By Packaging:

- Rigid Industrial Packaging

- Flexible Industrial Packaging

By End-Use Industry:

- Agriculture

- Automotive

- Building & Construction

- Chemical & Pharma

- Engineering

- Food & Beverages

- Metal Products

- Oil & Lubricants

- Plastic & Rubber

- Furniture

- Electronics

- E-Commerce

- Tobacco

- Other

By Region:

- GCC

- North Africa

- South Africa

- Rest of MEA

Sustainability Concerns To Encourage Gummed Taped Demand

Gummed paper tapes are made using the natural paper and are much easier to use as compared to the plastic packaging tapes. Due to mono materials, these tapes are easy to recycle along with waste carton boxes and therefore reduces recycling challenges over multi material packaging formats.

Unlike the traditional tapes, the gummed tapes do not need an additional synthetic adhesive for the sealing process and thereby proves an eco-friendly sealing option for the variety of end-user industries. This is expected to burgeon the sales of gummed tapes.

For Information On The Research Approach Used In The Report, Ask Analyst @ https://www.futuremarketinsights.com/askus/rep-gb-2821

Contact Us-

Unit No: 1602-006

Jumeirah Bay 2

Plot No: JLT-PH2-X2A

Jumeirah Lakes Towers

Dubai

United Arab Emirates