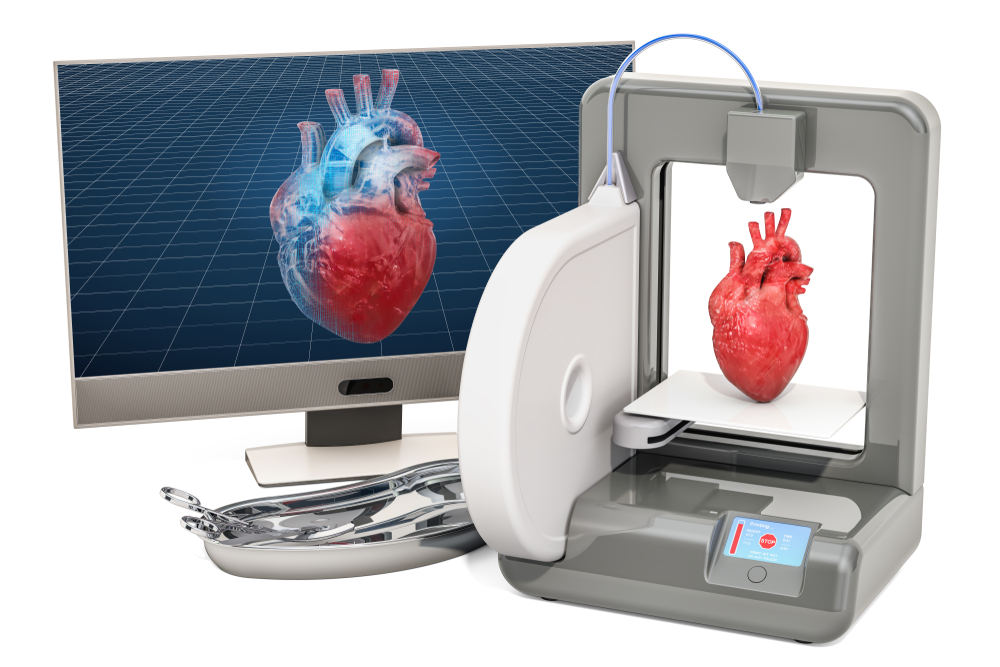

The 3D Printed Medical Devices Market is experiencing remarkable growth and innovation, revolutionizing the healthcare industry. This burgeoning sector leverages cutting-edge 3D printing technology to create custom-made medical devices, implants, and prosthetics, offering a multitude of benefits to both patients and healthcare professionals.

One of the key advantages of 3D printed medical devices is personalization. Unlike traditional mass-produced devices, 3D printing allows for the customization of implants and prosthetics tailored to an individual’s unique anatomy. This personalization enhances patient comfort and overall effectiveness, leading to improved treatment outcomes. Additionally, it reduces the risk of rejection or complications, which is especially critical in the field of organ transplantation and orthopedic surgeries.

Unleash the power of knowledge and transformation by accessing our Sample Report! https://www.futuremarketinsights.com/reports/sample/rep-gb-1501

Furthermore, 3D printing enables faster production and lower costs. Traditional manufacturing methods can be time-consuming and expensive. In contrast, 3D printing is more efficient, reducing lead times and production expenses. This not only benefits patients but also healthcare institutions looking to optimize their resources.

Over the course of the forecast period, the market for 3D-printed medical devices is anticipated to grow strongly at a CAGR of 16.3%. As of 2023, the market has a share of US$ 799.8 million, but by 2033, it’s expected to reach US$ 3.6 billion.

As the technology continues to advance, we can expect even more groundbreaking developments in the 3D Printed Medical Devices Market. From patient-specific implants to intricate surgical instruments, 3D printing is poised to play a pivotal role in shaping the future of healthcare, offering innovative solutions that improve patient care and outcomes.

Here are some key points about the 3D printed medical devices market:

- Customization and Personalization: 3D printing enables the creation of medical devices tailored to individual patient needs. This is particularly important in fields like orthopedics, where implants can be customized to fit a patient’s unique anatomy.

- Reduced Lead Times: Traditional manufacturing processes for medical devices can be time-consuming. 3D printing allows for faster prototyping and production, which can be critical in emergency situations or for patients with urgent needs.

- Complex Geometries: 3D printing can produce intricate and complex designs that would be difficult or impossible to achieve with traditional manufacturing methods. This is particularly beneficial for implants and prosthetics.

- Materials Diversity: Various types of materials, including biocompatible and bioresorbable materials, can be used in 3D printing medical devices. This allows for a wide range of applications, from dental implants to tissue scaffolds.

- Cost-Efficiency: While initial investments in 3D printing equipment can be high, the technology can often lead to cost savings in the long run, especially when it comes to producing low-volume, high-value medical devices.

Our Analyst Is Available To Help You With Any Inquiries Reach Out Anytime! https://www.futuremarketinsights.com/ask-question/rep-gb-1501

Incorporating 3D printed medical devices, which distribution channel reaps the greatest benefits?

The distribution channel that benefits the most from the employment of 3D printed medical devices can vary depending on several factors, including the type of medical device, its intended use, and the target market. However, there are several distribution channels that can see significant advantages from the integration of 3D printed medical devices:

- Direct-to-Hospital or Healthcare Facility: Many medical institutions, such as hospitals and clinics, may choose to work directly with 3D printing companies or manufacturers to produce custom medical devices. This eliminates the need for intermediaries and allows for faster customization and delivery of devices tailored to specific patient needs.

- Medical Equipment Suppliers: Established medical equipment suppliers and distributors can incorporate 3D printed devices into their product portfolios. This can expand their offerings, attract more customers, and enhance their competitiveness. They can work directly with 3D printing manufacturers to source and distribute these devices.

- Online Marketplaces: Online marketplaces for medical equipment and supplies, similar to platforms used for general consumer products, can benefit from the inclusion of 3D printed medical devices. These platforms can provide a wide range of options to healthcare professionals and streamline the purchasing process.

Key Contributors of the 3D Printed Medical Devices Market are:

- 3D Systems, Inc.

- Arcam AB

- Stratasys Ltd.

- FabRx Ltd.

- EOS GmbH Electro Optical Systems

- EnvisionTEC

- Cyfuse Biomedical K.K.

- Bio3D Technologies

Personalized Experiences Redefined: Our Customization Report Holds the Answers! https://www.futuremarketinsights.com/customization-available/rep-gb-1501

Key Segments:

By Application:

- Orthopaedic Implants

- Dental Implants

- Cranio-maxillofacial Implants

- Internal and External Prostheses

By Technology:

- Stereolithography (SLA) – Liquid-Based 3D Printing

- Selective Layer Sintering (SLS) – Powder-Based 3D Printing

- Digital Light Processing(DLP)

- Fused Deposition Modeling (FDM): Plastic Filament Extrusion Based

- PolyJet / InkJet 3D Printing

- Electronic Beam Melting (EBM)

By Distribution Channel:

- Hospitals

- Ambulatory Surgical Centers

- Diagnostic Centers

By Material Type:

- Plastics

- Thermoplastics

- Photopolymers

- Biomaterial Inks

- Polymers

- Ceramics

- Hydrogels

- Metals and Alloys

By Region:

- North America

- Latin America

- Europe

- Asia Pacific (APAC)

- The Middle East & Africa (MEA)

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 5000 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware – 19713, USA

T: +1-845-579-5705

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube