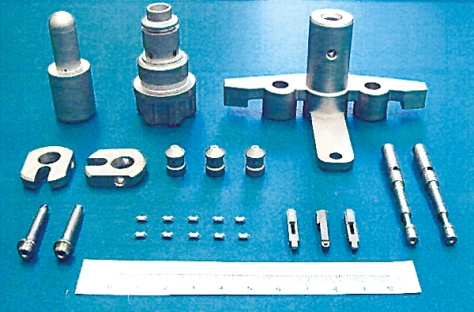

Powder Injection Molding (PIM) is an advanced manufacturing process used to produce intricate metal or ceramic components. It involves mixing fine powder with a binder, shaping the material through injection molding, and then removing the binder through debinding and sintering. PIM allows for high precision, cost-effective mass production of complex parts used in various industries, including automotive, medical, and electronics.

Powder injection molding (PIM) combines the benefits of traditional powder metallurgy and plastic injection molding, enabling the production of complex-shaped parts with high precision. The PIM market is witnessing steady growth due to the rising demand for miniaturized components in industries such as electronics, automotive, and healthcare, where PIM offers cost-effective manufacturing solutions.

The powder injection molding market is likely to grow with a double-digit CAGR over the entire forecast period. The global powder injection molding market size is expected to grow at an opulent CAGR of 9.3% over the projection period from 2022 to 2032. The growth of the market is attributed to the widespread application of PIM due to which new opportunities are coming on the way of manufacturers.

Power injection molding is an industrial manufacturing solution for the production of alloy, metal, and ceramic parts. Furthermore, this process is massively used on account of its advantages, such as cleaner product output over other processes. One of the primary factors driving the growth of the global powder injection molding market comprises of growing demand for miniaturized complex components to be used as high-performance materials pertaining to various end-user industries.

The rising demand for medical equipment has fueled the need for power injection molding in order to manufacture micro-parts. These parts are further used in various medical procedures and techniques. Invasive surgery, intravenous therapy, advanced drug delivery, and vascular therapy require precise equipment manufactured with state-of-the-art manufacturing methods.

Take a Deep Dive: Access Our Sample Report to Understand How the Shipping Industry and Green Hydrogen Initiatives Drive the Powder Injection Molding Market! https://www.futuremarketinsights.com/reports/sample/rep-gb-186

Key Takeaways

- The power injection molding market is segmented on the basis of its technology which includes ceramic injection molding (CIM) and metal injection molding (MIM). These technologies are predicted to bolster over the assessment period.

- The growth of the global powder injection molding market is anticipated to propel owing to the demand from applications such as automotive, medical, healthcare, aerospace, consumer products, industrial machinery, and others.

- Rising industrial expansion activities in the Asia Pacific and other regions are likely to augment growth in the market over the projection period. Furthermore, expansion in the machine manufacturing industry in the last few years serves as an opportunity for powder injection molding in various interrelated applications.

- On the basis of raw materials, the global powder injection molding market is categorized under the stainless steel, soft magnetic alloys, titanium alloys, and low-alloy steel segments. Raw materials are selected on the basis of their end-use industry where innovation in the material science industry has led to the expansion of application areas.

- Some of the primary end-usages that bolster the demand for powder injection molding processes include electronic gadgets, medical equipment, firearms, and automotive components.

- Intricate shapes of medical devices comprise specialized manufacturing methods. Moreover, the ability of the powder injection molding method to form precise shapes as compared to conventional manufacturing methods is supplementing the growth of the medical and healthcare application segment.

Competitive Landscape in Powder Injection Molding Market Research Report:

Major companies in the global powder injection molding market are focusing on technologically advanced solutions. New products are being launched with high-tech features in order to cater to a wider consumer base.

Key Players in Powder Injection Molding Market

- ARC Group

- Advanced Materials Technologies Pte. Ltd.

- Epsom Atmix Corporation

- PSM Industries Inc.

- Plansee Group

- Indo-US MIM Tec Pvt. Ltd.

More Insights into the Powder Injection Molding Market

Asia Pacific region is anticipated to dominate the global power injection molding market for ceramic and metal injection at a global level. The utilization of power injection molds is prevalent in the automotive industry. In this industry, the machine and machine-component manufacturers serve as the dominant market share end-user group for the powder injection molding process.

Are you looking for deep information related to the latest trends, drivers, and challenges? Speak to Our Analyst: https://www.futuremarketinsights.com/ask-question/rep-gb-186

The power injection molding market has been supplemented by the latest environmental regulations. These guidelines are mandatory for companies in order to streamline production methodologies and reduce emissions. As a consequence, the market for powder injection molding is growing as it produces parts to near-net shape, thereby eliminating secondary machining processes.

Increasing firearms utilization within the defense industry, specifically in the U.S. is anticipated to bolster powder injection molding industry growth in North America. In addition to that, Asia Pacific’s demand for powder injection molding is driven by the demand from electronics component applications.

Europe is expected to create impeccable growth opportunities over the evaluation period and is dominated by automotive applications. On the other hand, the North American powder injection molding market is dominated by medical & healthcare applications.

It has been concluded that the regional market of powder injection molding market varies on a broader spectrum due to the variation in technology along with the variation in end-user industries’ growth in the respective regions. Further, market participants are more focused to target respective end-user industries to manufacture specialized products.

Powder Injection Molding Market Key Segments

By Technology

- Ceramic injection molding (CIM)

- Metal injection molding (MIM)

By Application

- Automotive

- Medical

- Healthcare

- Aerospace

- Consumer products

- Industrial machinery

By Raw Material

- Stainless steel

- Soft magnetic alloys

- Titanium alloys

- Low-alloy steels

By Region

- North America

- Latin America

- Asia Pacific

- Japan

- Western Europe

- Eastern Europe

- Middle East & Africa

About FMI

Future Market Insights (ESOMAR certified market research organization and a member of Greater New York Chamber of Commerce) provides in-depth insights into governing factors elevating the demand in the market. It discloses opportunities that will favor the market growth in various segments on the basis of Source, Application, Sales Channel and End Use over the next 10-years.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware – 19713, USA

T: +1-845-579-5705

For Sales Enquiries: sales@futuremarketinsights.com

LinkedIn| Twitter| Blogs