In 2023, the global anti-corrosion bags market is anticipated to reach a valuation of approximately US$ 14.7 billion, driven by supply chain optimization efforts. Forecasts suggest a robust compound annual growth rate (CAGR) of 7.1% from 2023 to 2033, potentially leading to a market size of around US$ 29.3 billion by 2033.

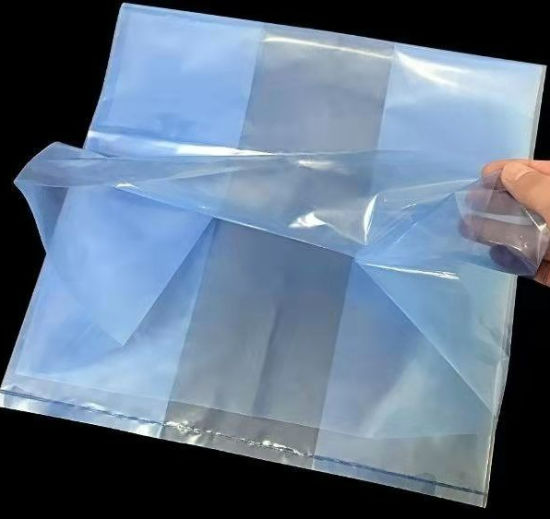

Anti-corrosion bags, also known as VCI (Volatile Corrosion Inhibitor) bags, are designed to protect metal parts and products from corrosion and rust during storage and transportation. These bags are made from specialized materials that release corrosion-inhibiting chemicals, creating a protective atmosphere inside the bag that prevents metal surfaces from corroding.

In a world where metals are essential components of everyday life, protecting them from the detrimental effects of corrosion is paramount. The Anti-corrosion Bags Market provides a solution that not only safeguards your investments but also extends the lifespan of your valuable items. In this article, we’ll delve into the intricacies of the anti-corrosion bags market, exploring its various aspects, benefits, and types.

Download the Sample Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-8891

Key Factors Driving the Anti-Corrosion Bags Market:

- Industrial Growth: The anti-corrosion bags market is closely tied to industrial activities, particularly in sectors like automotive, aerospace, manufacturing, and oil and gas. As these industries grow, the demand for anti-corrosion packaging solutions increases.

- Globalization of Supply Chains: With the globalization of supply chains, products often travel long distances and are exposed to varying environmental conditions. Anti-corrosion bags help protect metal components during transit and storage.

- Environmental Regulations: Stricter environmental regulations and the need for sustainable packaging solutions have driven innovation in anti-corrosion bags. Manufacturers are increasingly developing eco-friendly options.

- Technological Advancements: Advancements in materials and packaging technologies have led to the development of more effective and longer-lasting anti-corrosion bags.

- Cost Savings: Using anti-corrosion bags can lead to cost savings by reducing the need for additional corrosion protection methods, such as coatings or expensive storage environments.

Types of Anti-Corrosion Bags:

- VCI Bags: Volatile Corrosion Inhibitor bags release chemicals that form a protective layer on metal surfaces, preventing corrosion. They are commonly used for storing and shipping metal parts.

- Desiccant Bags: These bags contain desiccant materials to absorb moisture, which is a common cause of corrosion. They are often used in conjunction with VCI bags for added protection.

- Barrier Bags: Barrier bags are designed to provide a protective barrier against external factors such as moisture, oxygen, and other contaminants. They are used for sensitive metal components.

Market Trends and Future Outlook:

- The anti-corrosion packaging industry was witnessing innovation in sustainable and recyclable materials to align with environmental concerns.

- Increased use of digital technology for monitoring and maintaining the condition of products during shipping and storage.

- Growing adoption of anti-corrosion bags in the e-commerce industry, especially for the protection of metal products during online order fulfillment.

- Expansion of the anti-corrosion packaging market in emerging economies due to increased industrialization and globalization.

Request Customization:https://www.futuremarketinsights.com/customization-available/rep-gb-8891

In conclusion, the anti-corrosion bags market is expected to grow due to the increasing demand for protective packaging solutions for metal parts, machinery, and electronic components during transportation and storage. The use of anti-corrosion bags can extend the life of stored components and prevent damage, resulting in cost savings for companies. However, the high cost of anti-corrosion bags and the limited awareness of the benefits of anti-corrosion bags among end-users may limit the growth of the market.

Key Players:

- Gulmohar Pack-Tech India Pvt. Ltd.

- Northern Technologies International Corporation (NTIC)

- Smurfit Kappa

- H L Saw Mill

- NEFAB Group

- Acme Packaging

- Modi Polyfab Pvt Ltd.

- Pontus Pack Private Limited

Key Segments Profiled in the Anti-corrosion Bags Industry Survey

By Product Type:

- Zipper Bags

- Flat Bags

- Gusseted Bags

- Other Customized Bags

By Layer Type:

- Mono-layer

- Multi-layer

By Application:

- Households

- Building and Construction

- Consumer Goods

- Electronics and Electrical

- Automotive

- Pharmaceuticals and Medical Devices

Buy Now/Purchase: https://www.futuremarketinsights.com/checkout/8891

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 5000 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware – 19713, USA

T: +1-845-579-5705

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube