Imagine a world where industrial processes operate smoothly, even in the face of unexpected pressure surges or emergencies. Enter the Emergency Vent Cover Market, the silent guardian of safety in storage tanks and process vessels. These seemingly simple covers play a critical role by providing a controlled release mechanism, preventing catastrophic failures and safeguarding personnel, equipment, and the environment. Driven by stringent safety regulations, the growing demand for efficient storage solutions, and a rising focus on risk mitigation, the Emergency Vent Cover Market is experiencing steady growth. Let’s delve into the applications of emergency vent covers and explore the exciting trends shaping this dynamic market.

Applications of Emergency Vent Covers

Emergency vent covers come in various configurations and pressure ratings, catering to the specific needs of different industries and applications:

- Oil & Gas Industry: Storage tanks holding flammable liquids and gases require robust pressure relief mechanisms. Emergency vent covers prevent tank ruptures during overpressure events caused by factors like fire exposure or thermal expansion.

- Chemical Processing: Chemical plants handle volatile materials that can react violently if uncontrolled pressure builds up. Emergency vent covers provide a safe release mechanism, preventing explosions and safeguarding personnel and equipment.

- Food & Beverage Production: Large fermentation tanks and silos used in food and beverage production can generate excessive pressure. Emergency vent covers ensure a controlled release, preventing tank failures and protecting product integrity.

- Pharmaceutical Manufacturing: Strict safety protocols are paramount in pharmaceutical production. Emergency vent covers prevent accidental overpressure situations, safeguarding personnel and ensuring product quality.

- Water & Wastewater Treatment: Closed treatment tanks can experience pressure fluctuations. Emergency vent covers prevent tank ruptures and potential environmental contamination in case of unexpected pressure surges.

Get Exclusive Sample Copy of the Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-19394

A Market Releasing the Pressure: Growth Factors and Opportunities

The Emergency Vent Cover Market is experiencing a surge in popularity driven by several key trends:

- Stringent Safety Regulations: Governments worldwide are implementing stricter regulations mandating the use of pressure relief devices like emergency vent covers on storage tanks and process vessels. This ensures the safety of workers and the environment.

- Focus on Risk Mitigation: Companies are prioritizing proactive risk management strategies to minimize the potential for accidents and costly downtime. Emergency vent covers play a crucial role in mitigating pressure-related risks in storage and processing operations.

- Growing Demand for Efficient Storage Solutions: As industries strive for operational efficiency, the demand for larger and more efficient storage tanks is increasing. Emergency vent covers become even more critical for these larger vessels to ensure safe pressure management.

- Advancements in Technology: Manufacturers are constantly innovating, developing emergency vent covers with improved pressure relief capacities, automated triggering mechanisms, and better integration with advanced safety monitoring systems.

- Focus on Sustainability: Emergency vent covers contribute to sustainable practices by preventing accidental releases of hazardous materials and potential environmental damage.

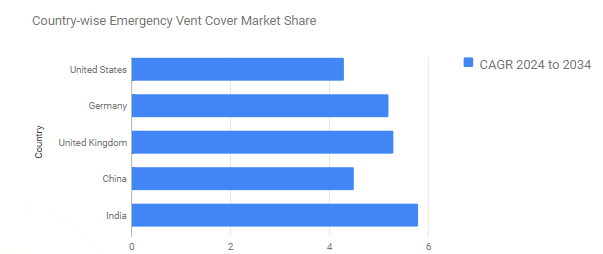

The global emergency vent cover market is poised for significant growth, with an estimated value of USD 587 million in 2024 and a projected compound annual growth rate (CAGR) of 4.80% from 2024 to 2034. By 2034, the market is anticipated to reach USD 938.1 million, reflecting the critical role these covers play in industrial safety systems across various sectors.

Challenges and Considerations

The Emergency Vent Cover Market also faces some hurdles:

- Proper Selection and Sizing: Selecting the right emergency vent cover with the appropriate pressure relief capacity is crucial for optimal safety. Improper sizing can render them ineffective.

- Regular Maintenance and Inspection: Emergency vent covers require regular maintenance and inspection to ensure they function flawlessly during emergencies. Implementing robust maintenance protocols is essential.

- User Training: Proper training for personnel on the functionality and limitations of emergency vent covers is necessary to ensure they are not accidentally disabled or tampered with.

Get Full Report Now: https://www.futuremarketinsights.com/checkout/19394