Industrial pumps are the unsung heroes of modern manufacturing, silently ensuring the flow of vital fluids that keep processes running smoothly. From colossal refineries to intricate microchip fabrication, these workhorses play a crucial role in diverse applications. Driven by rising industrial activity, increasing demand for efficient processes, and growing environmental concerns, the Industrial Pump Market is experiencing significant growth. Let’s explore the applications of industrial pumps and delve into the exciting trends shaping this dynamic sector.

The Power of Flow: Applications of Industrial Pumps

Industrial pumps come in a vast array of configurations, each designed to handle specific fluids and applications:

- Centrifugal Pumps: These versatile workhorses are the most common type, utilizing rotating impellers to create a centrifugal force that moves liquids. Applications include water transfer, chemical processing, and wastewater treatment.

- Positive Displacement Pumps: These pumps ensure precise and consistent flow by trapping and pushing fluid through a chamber. They are ideal for viscous liquids, slurries, and applications requiring high pressure. Examples include metering pumps for chemical injection and fuel delivery pumps in industrial engines.

- Reciprocating Pumps: These pumps utilize a piston-and-cylinder mechanism to create suction and pressure, well-suited for high-pressure applications like hydraulic systems and well drilling.

- Submersible Pumps: Designed to operate underwater, these pumps are critical for drainage applications, wastewater treatment facilities, and oil and gas extraction.

- Specialty Pumps: The industrial pump landscape also encompasses a wide range of specialty pumps, such as gear pumps for viscous fluids, peristaltic pumps for delicate biological samples, and vacuum pumps for creating low-pressure environments.

Get Exclusive Sample Copy of the Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-19049

A Market Flowing with Opportunity: Growth Factors and Future Trends

The Industrial Pump Market is experiencing a surge in popularity driven by several key trends:

- Rising Industrial Activity: As manufacturing, construction, and energy sectors expand globally, the demand for reliable and efficient pumps to handle various fluids increases, propelling market growth.

- Focus on Process Optimization: Industries are prioritizing efficiency and cost savings. High-performance pumps with improved flow rates and reduced energy consumption are in high demand to optimize fluid management within processes.

- Stringent Environmental Regulations: Regulations regarding emissions and wastewater treatment necessitate pumps that minimize leaks and enhance efficient fluid handling, driving demand for advanced pump technologies.

- Advancements in Pump Technology: Manufacturers are constantly innovating, developing pumps with improved materials for corrosion resistance, variable speed drives for precise flow control, and smart features for remote monitoring and diagnostics.

- Growing Adoption of Automation: The rise of automation in industrial processes necessitates pumps compatible with automated control systems, allowing for real-time flow management and improved process integration.

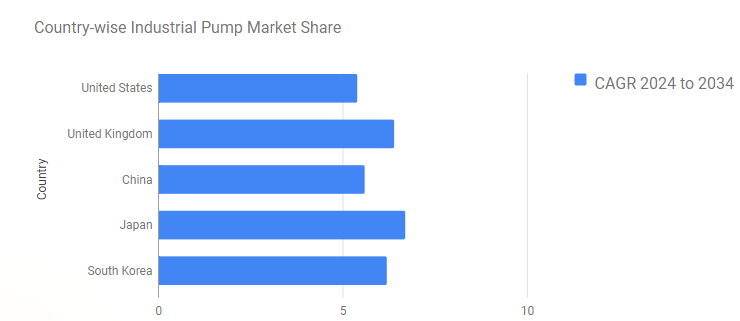

The global industrial pump market is expected to develop with a projected CAGR of 5.3% through 2034. In 2024, the market is expected to cross a valuation of USD 68.0 billion, and by 2034, it is estimated to touch USD 113.5 billion.

Key Companies in the Market

- Dover Corporation

- Ebara Corporation

- Flowserve Corporation

- Grundfos Holding A/S

- ITT Inc.

- Xylem

- Flowserve Corporation

- WILO SE

- KSB SE & Co. KGaA

- Sulzer Ltd

- Schlumberger Limited

- The Weir Group PLC

- ALFA LAVAL

- Pentair

- IDEX

- Baker Hughes Company

- SPX Flow

Challenges and Considerations

The Industrial Pump Market also faces some hurdles:

- Energy Consumption: Pumping operations can be energy-intensive. Selecting energy-efficient pumps and optimizing system design are crucial for minimizing energy consumption and environmental impact.

- Maintenance Needs: Proper pump maintenance is essential to ensure optimal performance and lifespan. Investing in training programs and preventative maintenance strategies can optimize pump operations and reduce downtime.

- Material Selection: Choosing the right pump material is critical for compatibility with specific fluids and operating conditions. Factors like corrosion resistance, temperature tolerance, and abrasive wear need to be considered.

Get Full Report Now: https://www.futuremarketinsights.com/checkout/19049