Metal stampings, those meticulously formed metal pieces, are the building blocks for countless products across various industries. The metal stamping market, driven by their versatility and efficiency, is experiencing steady growth. Let’s delve into the diverse applications of metal stampings and explore the exciting opportunities shaping this market.

Taking Shape Across Industries: Applications of Metal Stampings

Metal stampings offer a cost-effective and high-volume manufacturing solution for a wide range of components:

- Automotive: From car body parts like fenders and hoods to intricate engine components and brackets, metal stampings are a mainstay in the automotive industry.

- Electronics: Metal stampings form the chassis, heat sinks, and EMI/RFI shielding components that house and protect delicate electronic circuitry.

- Appliances: Durable and functional parts like washing machine agitators, oven racks, and refrigerator shelves are often precisely stamped from metal sheets.

- Construction: Metal stampings find use in building components like HVAC ductwork, roofing panels, and structural supports for walls and ceilings.

- Consumer Goods: From computer casings and tool components to bottle caps and cookware, metal stampings contribute to the functionality and aesthetics of countless consumer products.

Get Exclusive Sample Copy of the Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-812

A Market Stamped with Growth: Opportunities on the Horizon

The metal stamping market is experiencing a boom driven by several key trends:

- Rise of Automation: Increased automation in manufacturing processes necessitates high-precision and consistent metal parts, which metal stamping excels at producing.

- Demand for Lightweight Materials: The growing demand for lightweight vehicles and fuel-efficient products creates a need for lighter yet robust metal components that metal stamping can deliver.

- Focus on Miniaturization: As electronic devices and components continue to shrink, metal stamping technology allows for the creation of intricate and precise metal parts.

- Growing Demand in Emerging Markets: The expanding manufacturing base in developing economies creates a significant demand for cost-effective and versatile metal stamping solutions.

- Advancements in Metal Stamping Technology: Developments in high-speed stamping presses, laser cutting integration, and innovative die designs are leading to faster production times, increased efficiency, and more complex part geometries.

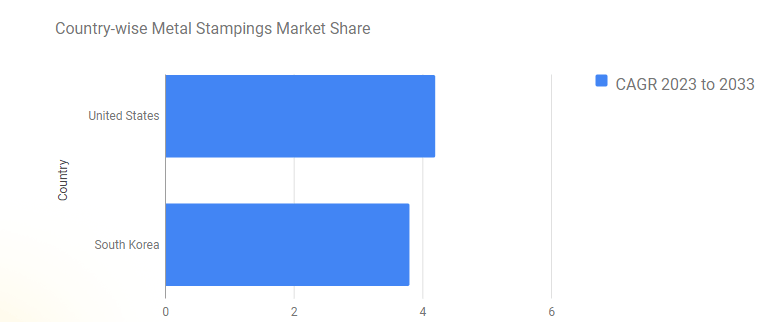

The Metal Stampings Market size is projected to be worth USD 419.7 Billion in 2023. The market is likely to surpass USD 635.8 Billion by 2033. According to Future Market Insights (FMI), the market is further expected to surge at a CAGR of 4.2% during the forecast period.

Challenges and Considerations

The metal stamping market also faces some challenges:

- Fluctuations in Metal Prices: The global metal market is susceptible to price fluctuations based on raw material costs and demand, impacting production costs for stamped parts.

- Tooling Costs: The upfront investment in high-quality stamping dies can be significant, especially for complex parts, which may deter smaller manufacturers.

- Environmental Regulations: Metal stamping processes generate scrap metal and require proper waste management strategies to comply with environmental regulations.

Get Full Report Now: https://www.futuremarketinsights.com/checkout/812