The global market for non-UV dicing tapes market is poised for significant expansion in the coming decade, driven by the increasing demand for miniaturization in electronic devices and the rapid growth of the Internet of Things (IoT). According to a recent market analysis, the market size is expected to reach USD 1.59 billion in 2023 and is projected to grow at a robust compound annual growth rate (CAGR) of 6.0%, reaching approximately USD 2.8 billion by 2033.

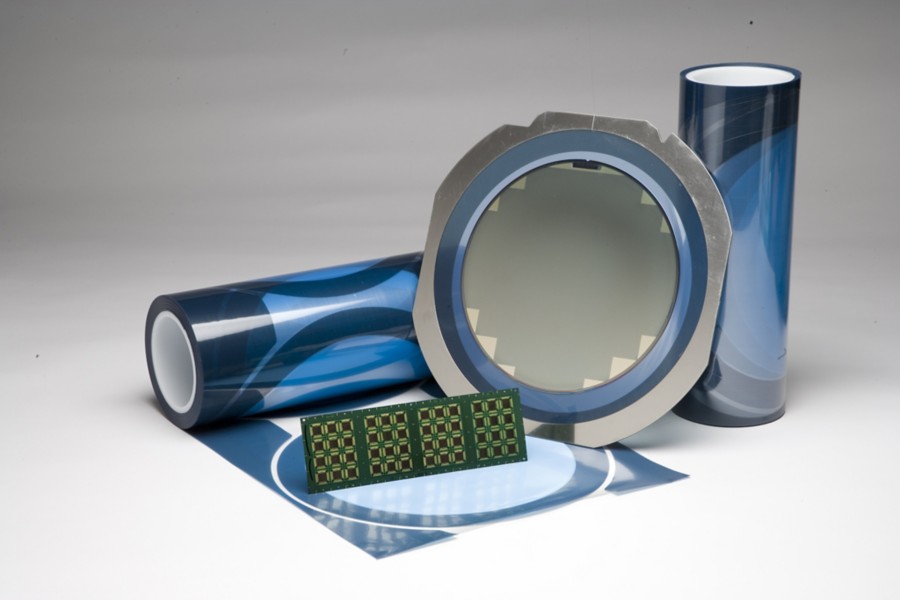

Non-UV dicing tapes play a crucial role in semiconductor manufacturing processes, facilitating the dicing and separation of semiconductor wafers into individual semiconductor chips. With the proliferation of IoT devices and advancements in miniaturization technologies, the demand for non-UV dicing tapes is expected to surge across various industries including electronics, telecommunications, and automotive.

The trend toward downsizing and the proliferation of Internet of Things (IoT) devices raise the need for non-UV dicing tapes as manufacturers search for dependable solutions to meet the stringent requirements of modern semiconductor fabrication. The convergence of IoT, 5G, and downsizing underscores the pivotal function of non-UV dicing tapes in enabling the seamless operation of next-generation electronic devices, hence driving the market’s rapid expansion.

Get a Sample of the Report:

https://www.futuremarketinsights.com/reports/sample/rep-gb-10866

Key points:

- Enhanced Yield and Quality: Non-UV dicing tapes offer superior adhesion and stability, minimizing wafer breakage and improving yield rates during the dicing process, ultimately leading to higher-quality chips.

- High-Temperature Resistance: These tapes are designed to withstand the high temperatures generated during dicing, ensuring reliable performance and avoiding tape residue or damage to the wafer surface.

- Minimal Residue and Clean Removal: Non-UV dicing tapes leave minimal residue on the wafer after removal, reducing the need for additional cleaning processes and enhancing overall production efficiency.

- Compatibility with Advanced Materials: The market provides non-UV dicing tapes that are compatible with various advanced semiconductor materials, such as silicon carbide (SiC) and gallium nitride (GaN), meeting the evolving needs of the industry.

- Customization Options: Non-UV dicing tapes can be customized to different wafer sizes and thicknesses, ensuring precise and secure bonding during the dicing process.

- Environmental Considerations: Many non-UV dicing tapes are designed with eco-friendly materials and processes, aligning with the industry’s focus on sustainability and reducing environmental impact.

Growth Opportunities in the Non-UV Dicing Tapes Market:

- Increased Semiconductor Demand: With the proliferation of electronics in various industries, the demand for semiconductor chips is on the rise, consequently driving the demand for non-UV dicing tapes used in semiconductor manufacturing.

- Technological Advancements: Ongoing advancements in semiconductor manufacturing technologies are creating opportunities for the development of more efficient and precise non-UV dicing tapes, enhancing productivity and yield rates.

- Expanding Electronics Industry: The expanding consumer electronics market, coupled with the growing adoption of IoT devices and wearable technology, presents significant growth prospects for the non-UV dicing tapes market as these devices require semiconductor components.

- Rising Automotive Sector: The automotive industry’s increasing integration of advanced electronics and semiconductor components in vehicles, including electric vehicles and autonomous driving systems, is driving the demand for non-UV dicing tapes for semiconductor packaging.

- Emerging Markets: Emerging economies, particularly in Asia-Pacific, are witnessing rapid industrialization and infrastructural development, creating a conducive environment for the growth of the non-UV dicing tapes market due to increased semiconductor manufacturing activities.

Upcoming Trends in the Non-UV Dicing Tapes Market:

- Miniaturization in Electronics: The trend towards miniaturization of electronic devices and components is driving the demand for thinner and more precise non-UV dicing tapes to enable the dicing of smaller semiconductor chips.

- Shift Towards Wafer-Level Packaging: The semiconductor industry is increasingly adopting wafer-level packaging techniques for cost reduction and improved performance, which necessitates advanced non-UV dicing tapes to facilitate the process.

- Demand for Environmentally Friendly Solutions: Growing environmental concerns are prompting manufacturers to develop eco-friendly non-UV dicing tapes with reduced environmental impact, aligning with sustainability goals and regulations.

- Integration of Advanced Materials: The integration of advanced materials such as polymers and nanomaterials in non-UV dicing tapes is poised to enhance their mechanical properties, thermal stability, and overall performance in semiconductor manufacturing processes.

- Focus on Process Automation: Automation and robotics are becoming integral in semiconductor manufacturing processes, including dicing operations. Non-UV dicing tapes compatible with automated handling systems are anticipated to gain traction as manufacturers strive for greater efficiency and accuracy.

Leading Key Companies:

Pantech Tape Co. Ltd.; Furukawa Electric Co. Ltd.; Mitsui Chemicals Inc.; AI Technology, Inc.; LINTEC Corporation; QES GROUP BERHAD; MTI Co. Ltd.; Han Kook Tapes Sdn Bhd; NIITO DENKO CORPORATION; Schenzhen Xinst Technology Co. Ltd.

Seize the Opportunity: Get Report Now for a Thorough Report

https://www.futuremarketinsights.com/checkout/10866

Market Segmentation:

By Region:

- North America

- Latin America

- Europe

- Middle East and Africa (MEA)

- East Asia

- South Asia

- Oceania

By Material Type:

- PVC

- PET

- PO

- Others (EVA, etc.)

By Thickness:

- 85-125 Micron

- 126-150 Micron

- Below 85 Micron

- Above 150 Micron

By Coating Type:

- Single Sided

- Double Sided

By Application:

- Wafer Dicing

- Package Dicing

- Others (Glass, Ceramics)

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer, Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware – 19713, USA

T: +1-845-579-5705

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube