The global pulp molding tooling market, valued at USD 923.5 Million in 2023, is set for a significant growth trajectory, with projections indicating it will surpass USD 1,622.9 Million by 2033, achieving a robust CAGR of 5.8% during the forecast period. This expansion is driven by the increasing demand for sustainable and eco-friendly packaging solutions amidst heightened environmental concerns and stringent regulations against single-use plastics.

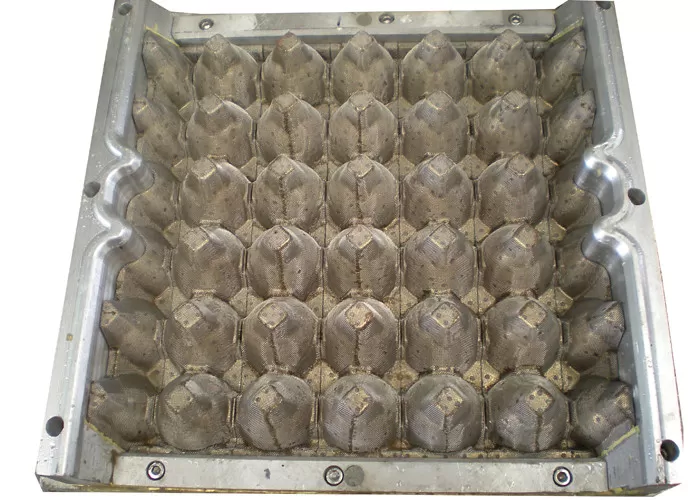

Pulp molding, also known as molded pulp or molded fiber, represents a vital shift in packaging, utilizing repurposed paper products to create sustainable alternatives. This process is increasingly favored for producing a variety of goods, including trays, containers, and protective packaging for electronic devices. A key trend propelling the market is the move towards automation, which enhances production efficiency, consistency, and reduces the likelihood of human error.

Key Drivers Fueling Market Demand:

- Environmental Awareness: As consumers grow more conscious of the environmental impacts of plastic packaging, there is a marked shift towards biodegradable solutions. Pulp molding tooling offers an eco-friendly alternative by utilizing recycled and compostable paper materials.

- Rising Disposable Income: The surge in disposable income, particularly in emerging markets across Asia-Pacific and Latin America, is driving demand for packaged consumer goods. Pulp molded packaging presents a cost-effective and environmentally sustainable option for these markets.

- Sustainability and Resource Management: Pulp molding tooling supports optimal use of recycled paper waste, reducing landfill burden and conserving natural resources, making it a cornerstone of sustainable waste management practices.

- Niche Market Penetration: The versatility of pulp molding tooling allows manufacturers to cater to niche markets requiring specialized packaging, such as the healthcare and pharmaceutical sectors, opening new avenues for market expansion.

- Superior Protection for Fragile Goods: The exceptional cushioning and shock-absorbing properties of pulp molding tooling make it an ideal choice for packaging fragile and delicate items.

Challenges and Restraints:

Despite its benefits, the market faces challenges, including the fragility of pulp-molded products, which may require additional packaging to prevent damage during transit. Additionally, the slower production cycle of pulp molding processes, coupled with the moisture absorption properties of the material, presents limitations, particularly in regions with high humidity or industries needing moisture-resistant packaging.

Emerging Opportunities:

The market is witnessing parallel growth opportunities, driven by the global shift towards sustainability and the demand for biodegradable packaging solutions. Notably, the medical and healthcare industries present significant growth potential, as pulp molded packaging offers cost-effective, sustainable, and customizable options for sterile and protected packaging needs.

Furthermore, ongoing research and development in material science and coating technologies are poised to enhance the performance and functionality of pulp molded products, addressing existing limitations and expanding their applicability across various industries.

Key Trends Shaping the Market:

- Automation and Scalability: Advances in automation technology are driving the market, enabling manufacturers to optimize production processes, enhance efficiency, and achieve higher output rates.

- Expanding Applications: Beyond traditional uses, pulp molding tooling is making inroads into new industry verticals such as electronics, cosmetics, personal care, and home appliances.

- Smart Technology Integration: The incorporation of smart technologies into pulp molding tooling processes is a noteworthy trend, offering real-time monitoring, predictive maintenance, and process optimization for enhanced productivity and consistency.

Automotive & Healthcare Shaping the Growth of Market

The automotive and healthcare industries are playing an important role in determining the growth of the pulp moulding tooling market, owing to their particular requirements and growing emphasis on sustainability and efficiency. Furthermore, pulp molding tooling allows for the fabrication of interior components such as door panels and storage compartments, which provide advantages like as weight reduction, cost effectiveness, and design freedom. Due to their inherent benefits, pulp moulded packaging and products are in high demand in the healthcare industry. Pulp moulding tooling is used to create sanitary and sterile packaging for medical devices, laboratory equipment, and pharmaceutical products. These packaging solutions assure the integrity and safety of the contents throughout transportation and storage while meeting the healthcare sector’s demanding regulatory standards. The automotive and healthcare industries’ particular requirements, together with their commitment to sustainability and efficiency, are dictating the expansion of the pulp moulding tooling industry. This involves optimising production processes, using environmentally friendly materials, and customising designs to match the needs of automotive and healthcare firms.

Key Players:

Shurcon Technology

Pacific Pulp Molding, Inc

Atlantic Pulp

MFT-CKF, Inc.

Pulp Moulding Dies Inc.

Keiding, Inc.

TPM-USA LLC.

Qisheng Thermoforming Machinery Co.,Ltd

Access Full Report: https://www.futuremarketinsights.com/reports/pulp-molding-tooling-market

Segmentation Analysis of the Pulp Molding Tooling Market

Tool Type:

- Single-Face tooling

- Transfer Tooling

- Progressive Tooling

- Rotary Tooling

- Custom Tooling

Application:

- Trays

- Boxes & Containers

- End Caps

- Cups & Bowls

- Plates

- Others (Drink Carriers, etc.)

End Use:

- Food & Beverages

- Egg Packaging

- Wine Packaging

- Fruit Packaging

- Electrical & Electronics

- Automotive

- Health Care

- Cosmetics & Personal Care

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer, Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware – 19713, USA

T: +1-845-579-5705

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube