As per NCBI, the number of people suffering from diabetic retinopathy will increase from 126.6 Mn in 2010 to 191 Mn by 2030. It also states that VTDR (Vision-threatening Diabetic Retinopathy) will witness an increase from 37.3 Mn to 56.3 Mn in the same period.

The above-mentioned figures, coupled with an influx of ophthalmic diagnostic centres in the countries like India and China (homes to the 2 top-seeded diabetic patients) are expected to drive the ophthalmic diagnostic equipment market in the forecast period.

Plus, the reimbursement scenario regarding eye care treatment is improving in developed and developing countries alike. Initially, reimbursement was possible only if there was a hospital stay for at least 24 hours.

However, the present scenario is such that LASER technology enables single-day treatment and insurance coverage is applicable therein. So, people in low-income countries will also not shy away from availing eye care treatments.

Key players

Key market players covered in this report are TOPCON CORPORATION, Carl Zeiss Vision International GmbH, Ellex, Quantel Medical Inc, NIDEK CO., LTD, HAAG-STREIT GROUP, Halma plc, Coburn Technologies Inc. and Kowa Company Ltd. Major players in the ophthalmic diagnostic equipment market focus on enhancing their global and regional presence through strategic acquisitions and mergers, and operational expansion.

To remain ‘ahead’ of your competitors, request for a sample – https://www.futuremarketinsights.com/reports/sample/rep-gb-771

Key Takeaways of Ophthalmic Diagnostic Equipment Market Study

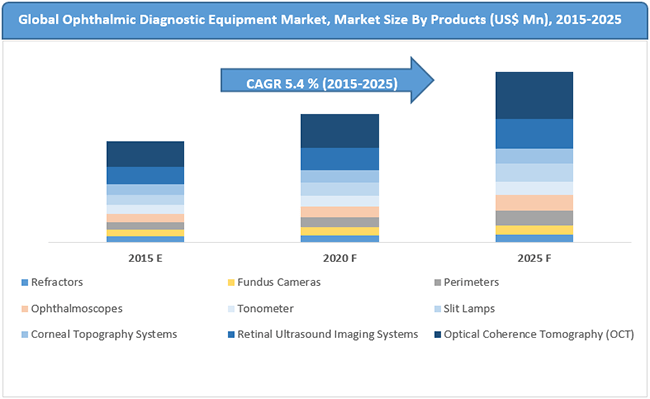

- The optical coherence tomography (OCT) held the largest share in the global ophthalmic diagnostic equipment market in 2019

- North America and Europe are expected to hold close to 30% of the global ophthalmic diagnostic equipment market in 2020 and the trend is expected to continue In the forecast period

- Asia Pacific expected to witness an exponential growth in the forecast period

“Increasing eye-related disorders coupled with market players focusing on technologically advanced ophthalmic diagnostic equipment are expected to substantiate the global ophthalmic diagnostic equipment market”, says FMI analyst.

Expansion and Visibility: Indigenous Strategies for Market Players

The ophthalmic diagnostic equipment market players are focusing on qualitative expansion and visibility to sustain their foothold in the ophthalmic diagnostic equipment market. Some of the steps taken on this count include:

- In June 2020, IBM Watson partnered with Japan-based Topcon Corporation in order to fast-track the development of products and services that improve the diagnosis, and treatment of eye disease, ultimately improving access for better patient care.

- In June 2020, Essilor collaborated with Michelin for jointly launching an UN-certified awareness campaign named “Together for safe mobility: Check your vision, check your tires”. The basic objective is to throw light on good vision apart from good tires. This campaign is likely to increase the demand for ophthalmic diagnostic equipment worldwide as UN has officially recommended road safety goals at a global level.

- Ellex is working in close collaboration with the ophthalmic physicians across the globe regarding minimally invasive options for treatment of glaucoma.

Get a Customized Scope to Match Your Need Ask an Expert- https://www.futuremarketinsights.com/ask-question/rep-gb-771

Key Segment

By Product Type

- Fundus Cameras

- Retinal Ultrasound Imaging Systems

- Refractors

- Slit Lamps

- Perimeters

- Ophthalmoscopes

- Tonometer

- Optical Coherence Tomography (OCT)

- Corneal Topography Systems

By End User

- Hospitals

- Clinics

- Ambulatory Surgical Centers

For critical insights, request for PDF Brochure: https://www.futuremarketinsights.com/reports/brochure/rep-gb-771

By Region

- North America

- Latin America

- Europe

- East Asia

- South Asia

- Oceania

- Middle East and Africa